There's nothing like slipping into a piece of clothing that feels like it was made just for you. That's where the magic of fit testing comes in.

Fit testing for custom women's underwear is essential to ensure the garment meets precise comfort, style, and performance standards. This process allows for necessary adjustments in size, elasticity, and design, reducing returns and enhancing customer satisfaction.

I remember the first time I tried on a pair of custom-fitted underwear. It was a revelation—a perfect blend of comfort and style that I hadn't experienced before. This is why fit testing is so crucial. It’s not just about getting the right size; it’s about understanding how different fabrics stretch, how seams sit against the skin, and ensuring that every detail, from the waistband to the leg openings, contributes to the overall feel of the garment. When manufacturers take the time to get this right, it doesn’t just reduce returns—it creates a bond of trust with customers who know they're getting something special. For retailers and designers, it’s a golden opportunity to stand out in a crowded market by offering products that truly meet the needs and desires of their clientele.

Fit testing reduces returns for custom underwear.True

Fit testing ensures the garment meets comfort standards, reducing returns.

Custom underwear fit testing is only about style.False

Fit testing addresses comfort, performance, and style, not just style.

How Does Fit Testing Enhance Customer Satisfaction?

Ever wondered how the perfect fit can transform a customer’s experience and loyalty? Let’s dive into the fascinating world of fit testing!

Fit testing enhances customer satisfaction by tailoring products to individual needs, improving comfort, reducing returns, and boosting brand loyalty. It identifies potential issues before production, optimizing both quality and customer experience.

Understanding Fit Testing

I remember the first time I realized just how important fit testing was. It was during a shopping trip when I tried on a pair of jeans that seemed to be crafted just for me. That perfect fit—hugging all the right places—made me feel like a million bucks. Fit testing, whether in fashion or personal protective equipment (PPE), serves this exact purpose. It's a quality assurance process ensuring products are not just meeting but exceeding user expectations by evaluating size, comfort, and functionality.

Benefits of Fit Testing for Customers

- Personalization: Imagine getting a product that feels like it was made just for you. By customizing products based on fit test results1, companies can provide that personalized touch we all love, enhancing customer satisfaction.

- Comfort and Performance: Remember those jeans? Their perfect fit meant they were not only comfortable but also allowed me to move freely, boosting their performance. The same goes for any product—proper fit can significantly enhance its performance and usability2, leading to happier customers.

- Reduced Returns: We’ve all had that frustration of returning something that didn’t meet our expectations. Products that fit well eliminate this hassle, meeting expectations from the get-go.

Benefits of Fit Testing for Businesses

| Aspect | Description |

|---|---|

| Cost Efficiency | Reduces the need for costly reworks by identifying issues early. |

| Brand Loyalty | Satisfied customers are more likely to return and recommend the brand. |

| Market Alignment | Ensures products align with current market trends and consumer demands. |

Fit testing not only refines products but also positions a company strongly in the market by aligning offerings with consumer trends3. It's a proactive approach that builds trust and invites repeat business.

Practical Examples

- Fashion Industry: Think about how brands adjust features like waistband elasticity or seam placement after fit tests, making sure garments flatter diverse body shapes.

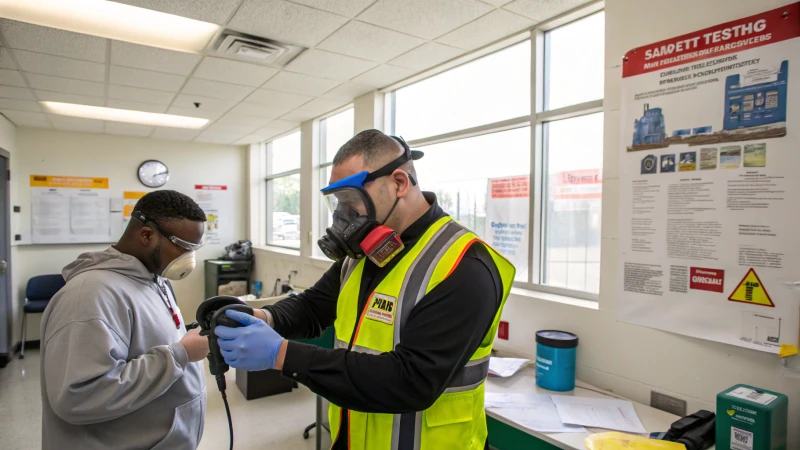

- Safety Equipment: PPE manufacturers ensure gear like respirators or helmets don’t just protect but also feel right during wear.

By understanding and implementing effective fit testing strategies, businesses can significantly enhance their customer satisfaction metrics and cultivate long-term customer loyalty. It’s like giving customers that perfect pair of jeans feeling every single time.

Fit testing reduces product returns.True

Fit testing ensures products meet customer expectations, lowering return rates.

Fit testing increases production costs.False

It identifies issues early, reducing costly reworks and saving money.

What Are the Key Components of a Successful Fit Test?

Fitting personal protective equipment is like finding the perfect pair of jeans—it has to be just right. But what makes a fit test successful?

A successful fit test means choosing the right respirator, training users effectively, conducting both qualitative and quantitative tests, and ensuring adherence to OSHA standards. Keeping detailed records and scheduling regular retests are crucial for maintaining ongoing safety.

Choosing the Right Respirator

Selecting a respirator feels a bit like trying on shoes—you need to find that perfect fit. I remember the first time I had to choose one; the options seemed endless! Each model fits differently, so offering a variety of sizes and styles is key to ensuring everyone finds their perfect match. Understanding respirator types4 is crucial because, just like shoes, what's comfortable in one situation might not work in another.

Training and Education

When I first learned about respirators, I didn't know how critical proper training was. It turns out, learning how to wear these things correctly is a bit like learning to ride a bike—you need practice! Training sessions are vital because they help users nail down the right techniques, such as strap placement, which can make or break a good seal.

Qualitative vs. Quantitative Fit Testing

Fit testing reminds me of taste-testing coffee. There's the qualitative test, which relies on your senses—it's straightforward but not always precise. Then there's the quantitative test, which is like having a machine gauge exactly how much sugar is in your cup. It measures leakage around the face seal, offering more detailed data.

- Qualitative Fit Test: A pass/fail test that relies on sensory detection of a test agent—simpler but less precise.

- Quantitative Fit Test: Uses machinery for measuring leakage around the face seal for detailed data analysis.

Each method has its pros and cons5 depending on workplace settings and available resources.

Ensuring Compliance with OSHA Standards

Following OSHA standards is non-negotiable, kind of like wearing a seatbelt. This includes keeping records of tests and making sure that everyone who needs a respirator is tested and retested as needed.

| Component | Description |

|---|---|

| Documentation | Record keeping of results and test dates |

| Regular Retesting | Ensures ongoing protection as facial features change |

| User Feedback | Gathering user experiences for continuous improvement |

Documentation and Continuous Improvement

Good documentation feels like writing in a diary; it tracks the journey and highlights areas needing improvement. Regular reviews can pinpoint trends in fit failures, prompting adjustments in respirator selection6 or training methods.

The Role of Technology

Technology in fit testing is like having a smartwatch for health tracking—it offers real-time feedback and insights. Investing in advanced tools can significantly improve safety outcomes, giving peace of mind that everything's functioning as it should.

In summary, understanding these components not only ensures regulatory compliance but also enhances worker safety, much like how maintaining your car ensures a smooth ride.

Choosing the right respirator is optional.False

Selecting the correct respirator is crucial for effective fit and safety.

OSHA standards require regular retesting.True

Regular retesting ensures continued protection as facial features change.

How Can Fit Testing Reduce Product Returns?

Have you ever had a customer return a product because it didn't fit just right? It’s frustrating, right? Fit testing might just be the game-changer you need to cut down those pesky returns and boost satisfaction.

Fit testing is like giving your products a dress rehearsal. By checking comfort and functionality before they hit the shelves, you can slash return rates, make design tweaks for a better fit, and build trust with your customers.

The Importance of Fit Testing

I remember the first time I tried on a pair of shoes that looked fabulous online but turned out to be a nightmare for my feet. It was then that I realized how critical fit testing is, especially in industries like apparel and footwear. By conducting thorough fit tests7, companies can preemptively tackle size discrepancies, material discomfort, and design flaws that often lead to returns.

Benefits of Fit Testing

| Benefit | Description |

|---|---|

| Reduced Returns | Helps identify potential issues before mass production, lowering return rates. |

| Enhanced Comfort | Ensures the product feels good, boosting customer satisfaction. |

| Design Improvement | Allows for adjustments in design based on real-world feedback. |

| Cost Efficiency | Saves money by avoiding reworks and unsellable stock. |

Real-World Applications

Let me share a story about customized women's underwear. Imagine spending months designing a line only to discover they don't meet the varied body shapes and preferences of your customers. That's where fit testing8 steps in. By evaluating factors like waistband elasticity and fabric stretch, brands can ensure a perfect fit.

- Tailored Adjustments: Brands can tweak features such as seam placement and leg openings based on feedback.

- Market Alignment: Testing ensures products align with market demands, reducing the chances of returns.

Industry Insights

A report from the apparel sector reveals that companies implementing fit testing experience up to a 30% reduction in returns. This not only saves costs but also enhances customer loyalty9 by building trust in product quality.

In summary, fit testing is your backstage pass to ensuring products hit the mark before they reach your customers. It’s a proactive approach that helps manufacturers and retailers improve their offerings, enhance customer satisfaction, and reduce return rates by making sure each product fits well and meets expectations. It's like giving your products the best chance to shine and your customers the joy of finding the perfect fit.

Fit testing reduces product return rates by 30%.True

Industry reports show fit testing can cut returns by up to 30%.

Fit testing increases production costs significantly.False

Fit testing saves costs by preventing reworks and unsellable stock.

Why Is Fit Testing Important for Brand Trust and Reputation?

Ever wonder why some brands seem to get it right every time, building trust effortlessly with their consumers?

Fit testing is crucial for brand trust and reputation as it ensures products meet consumer expectations for comfort and performance, reducing returns and increasing satisfaction.

The Role of Fit Testing in Consumer Satisfaction

I remember the first time I bought a pair of custom-fit jeans online. The anticipation was real, but so was my apprehension about whether they'd fit as promised. When they arrived, slipping into them felt like a dream—they hugged all the right places and I felt like they were made just for me. That’s the magic of effective fit testing. It’s about ensuring products adapt seamlessly to our diverse shapes and styles, so every customer feels that same satisfaction.

Fit testing is essential in determining whether a product meets the comfort and performance needs of its target audience. This practice allows brands to assess how well products adapt to various body shapes and preferences, ensuring optimal comfort10.

| Aspect | Importance |

|---|---|

| Size | Ensures correct fit for diverse body types |

| Elasticity | Provides comfort and durability during use |

| Design Details | Meets style expectations and enhances product appeal |

How Fit Testing Influences Brand Trust

There was this one time I trusted a brand so much that I didn’t even hesitate to buy their latest release. Why? Because they’d never let me down before. Fit testing is at the heart of building that trust. It helps brands consistently deliver products that not only fit well but feel like they were made just for me—reducing the likelihood of those dreaded returns.

Consumers are more likely to trust brands that consistently deliver products that fit well. Fit testing reveals areas where adjustments are needed, reducing potential for returns and dissatisfaction. This proactive approach helps maintain a positive brand image11.

- Reduced Returns: Aligning product specifications through rigorous fit testing slashes return rates.

- Enhanced Satisfaction: Customers love when products cater perfectly to their needs without hassle.

Economic Benefits of Fit Testing

Back in my early days working in product development, I learned how costly mistakes can be if not caught early. Fit testing shines here, offering brands a chance to catch potential issues before they snowball into expensive reworks. This kind of efficiency reinforces reliability—something every customer values deeply.

Beyond consumer satisfaction, fit testing offers economic advantages for brands. Identifying potential issues early helps avoid costly reworks and waste, leading to more efficient production processes. This efficiency not only saves resources but also reinforces a brand's reliability12.

- Cost Efficiency: Early detection of design flaws prevents expensive post-production corrections.

- Market Alignment: Products that meet market demands can be released with confidence, solidifying brand credibility.

Best Practices for Implementing Fit Testing

To truly reap the rewards of fit testing, it's crucial to stay ahead with regular updates and innovations. I always found value in partnering with industry experts to refine our processes and keep our standards in check. These collaborations ensure we’re not just meeting but exceeding customer expectations in a fast-paced market.

To maximize the benefits of fit testing, brands should adhere to best practices that align with their goals for brand reputation. Regular reviews and updates to fit standards ensure products remain relevant in a fast-evolving market. Consider collaborating with industry experts13 to refine testing protocols.

- Regular Updates: Continuously review fit standards to accommodate changing consumer preferences.

- Expert Collaboration: Engage professionals to enhance testing accuracy and reliability.

Fit testing reduces product return rates.True

Thorough fit testing aligns products with consumer expectations, minimizing returns.

Brands rarely benefit economically from fit testing.False

Fit testing identifies issues early, saving costs on reworks and increasing efficiency.

Conclusion

Fit testing is vital for custom women's underwear, ensuring comfort and style while reducing returns. It enhances customer satisfaction by allowing necessary adjustments based on individual preferences.

Discover how fit test results guide product personalization to enhance consumer satisfaction. ↩

Learn about the direct correlation between a product's fit and its performance from industry experts. ↩

Explore how fit testing keeps products relevant and competitive in the ever-changing market. ↩

Explore different respirator types to find the best fit for various workplace hazards. ↩

Learn about the advantages and limitations of each fit testing method. ↩

Discover guidelines for selecting appropriate respirators to enhance user safety. ↩

Understanding the role of fit testing in product development can provide insights into its effectiveness in reducing returns. ↩

Learn how fit testing is applied in the customized underwear industry to enhance product satisfaction. ↩

Explore how fit testing contributes to building customer loyalty by ensuring high-quality product experiences. ↩

Exploring this link will reveal why comfort is a key factor in consumer satisfaction and loyalty. ↩

This link provides insights into the impact of brand image on purchasing decisions and loyalty. ↩

Understanding reliability's role will help you see why it’s crucial for maintaining consumer trust. ↩

This will connect you with professionals who can offer valuable insights into effective fit testing. ↩