Entering the world of custom underwear creation is thrilling. However, unexpected expenses often catch people by surprise.

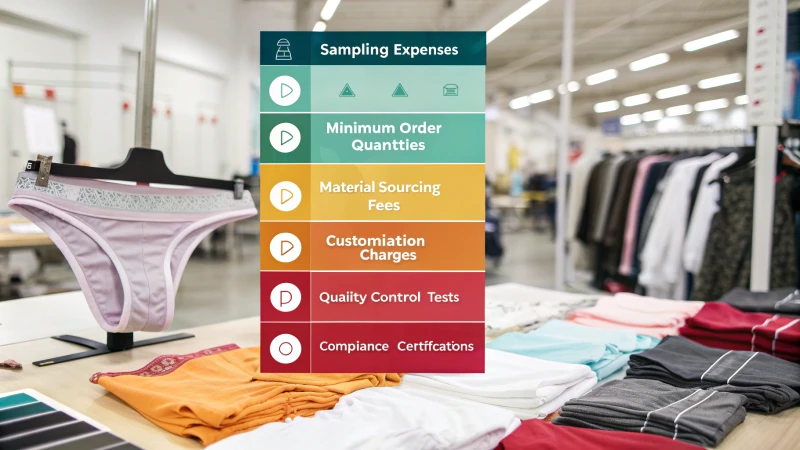

Hidden costs in custom underwear production include sampling fees, minimum order quantities, charges for sourcing materials, customization costs, quality control expenses and compliance certifications. Knowing these costs helps you budget better. This knowledge probably helps you plan for a successful launch.

When I started this journey, surprising expenses caught me off guard. Understanding these costs felt like uncovering a mystery. Let's explore each hidden cost, so your path to success becomes easier.

Sampling expenses are a hidden cost in custom underwear.True

Sampling costs arise from creating initial product samples for evaluation.

Minimum order quantities are not a hidden cost factor.False

Minimum order quantities can lead to unexpected costs in production.

How Do Sampling and Prototyping Costs Affect Your Budget?

Creating a budget for fashion projects feels like organizing a large celebration. Perfection is the goal, yet unexpected expenses often appear.

Sampling and prototyping might surprise you with high costs. They really alter your budget. Fabric expenses and labor for skilled artisans increase rapidly. Each change in the design demands more money.

Understanding the Cost Components

Entering product development, especially in fashion, taught me that sampling and prototyping are both very important and expensive. They resemble a practice run before the main event - absolutely necessary for everything to go smoothly. Just like any good practice, different parts raise costs.

| Component | Description |

|---|---|

| Materials | Fees for fabrics and specialized materials |

| Labor | Charges for skilled workers to create prototypes |

| Iteration | Costs incurred from multiple design revisions |

Each of these elements contributes uniquely to the total expenses.

Material Costs: A Major Expense

Imagine finding the perfect fabric for your custom underwear line, only to see its very high price. Picking the right material is essential, but special fabrics probably increase expenses a lot. Exploring sourcing options1 that give bulk discounts or choosing local suppliers helps reduce shipping fees.

Labor Charges: The Hidden Factor

Creating a prototype isn't just stitching pieces together. It requires skilled workers who know the details of quality and precision, which usually leads to higher labor expenses. If you’re like me, you probably want several versions for that ideal fit.

Tip: Working with manufacturers who provide detailed cost analysis2 helps avoid unexpected expenses.

The Iteration Challenge

Many nights I spent changing designs to find that “aha!” moment. Each version isn’t only about creativity - it involves resources and time, often increasing costs more than expected. Trying strategies like rapid prototyping3 helped me make this process quicker, saving both time and money.

Managing Budget Impact

Handling these costs effectively needs a strategic approach. Here’s what helped me:

- Forecast Iterations: Estimating possible revisions became a habit and I included them in my budget.

- Negotiate Contracts: Getting flexible deals with suppliers allowed me to accommodate changes without big penalties.

- Optimize Designs: I aimed at efficiency and cost-cutting from the start to reduce unnecessary versions.

Sampling and prototyping seem like big challenges, but with careful financial planning, they become manageable steps toward great quality. Understanding these costs and taking early action reduced their impact on my budget and kept my project moving forward.

Material costs are the least significant expense.False

Materials often constitute a major part of sampling and prototyping costs.

Iteration costs can inflate your budget.True

Multiple design revisions increase both time and financial expenditure.

What Are Minimum Order Quantities (MOQs) and Why Do They Matter?

Ever wonder why suppliers insist on those pesky minimum order quantities? Let me break it down for you.

Minimum Order Quantities (MOQs) mean the smallest number of units you have to purchase from a supplier at once. MOQs play an important role. MOQs help suppliers run operations efficiently. They help keep costs under control. Inventory management becomes easier with MOQs.

The Basics of MOQs

I remember when I first entered the business world; MOQs looked like a big, scary number affecting my budget. But as I learned more about manufacturing, I saw that they are not random. Minimum Order Quantities show the smallest batch size you order from a supplier. Suppliers set MOQs to cover their production costs well. Picture a factory requiring a minimum order of 100 units because smaller orders would not be profitable.

MOQs can vary widely depending on factors like industry standards, production costs, and the complexity of the product. Understanding industry norms4 really helps you predict what MOQs you will face.

Why MOQs Matter

MOQs might seem like a barrier, especially when starting or trying new products. But believe me, they are crucial for balancing supply and demand. For suppliers, MOQs allow cost-effective production. For buyers, meeting these quantities can be hard, particularly for startups with limited funds.

Consider a brand introducing a custom-designed men's underwear line5. They may need to order more than planned, which can stretch the budget and complicate stock management.

Strategies for Managing MOQs

Negotiation with Suppliers:

Communication matters. Approaching suppliers with a long-term partnership might lead to lower MOQs.Partnering with Other Buyers:

Once, I joined forces with another business needing similar items to meet MOQs together. We shared costs and benefits.Assessing Supplier Flexibility:

Some suppliers offer mixed orders or tiered pricing to manage costs while achieving minimum needs.

| Strategy | Benefits |

|---|---|

| Negotiation | Potentially reduced MOQs through long-term commitments |

| Partnering with Other Buyers | Shared costs, ability to meet higher MOQs without increasing individual risk |

| Supplier Flexibility | Mixed orders and tiered pricing to manage costs effectively |

Exploring flexible pricing models6 helped many brands, mine included, improve supply chain tactics.

Examples of MOQs Impacting Business Decisions

In fast-changing industries like fashion, where styles shift quickly, MOQs can greatly affect business plans. Companies must decide whether to accept higher initial costs or find suppliers that better match their volume needs.

For example, a new entrepreneur7 launching an online store might look for suppliers with smaller MOQs to test the market without using too many resources.

Understanding these situations taught me that strategic planning is crucial for managing resources well and meeting supplier expectations.

MOQs ensure cost-effective production for suppliers.True

MOQs help suppliers cover production costs by requiring bulk orders.

Startups often find MOQs easy to meet.False

Startups may struggle with MOQs due to limited capital and resources.

How does material sourcing affect your production timeline?

Do you ever think about why your production schedule feels like a roller coaster ride? The materials you choose could be the reason. Maybe it really is the materials.

Finding materials greatly impacts production schedules. It influences how long things take, saves money and keeps the supply chain stable. Good management helps avoid delays. Planning is critical too. Timely delivery matters.

Understanding Lead Times in Material Sourcing

Lead times mean the period from ordering to receiving materials. These times impact your production schedule greatly. If suppliers are across the globe or materials need special prep, knowing lead times is essential. I recall a stressful project where we sourced materials from far away. Every day felt like a waiting game, hoping for a delivery update. I learned this lesson hard when a delay pushed back a product launch.

| Factors Affecting Lead Times | Description |

|---|---|

| Supplier Location | Proximity to production site can reduce shipping time. |

| Material Complexity | Specialized materials may require longer preparation times. |

| Order Volume | Larger orders might take more time to fulfill. |

The Role of Cost Efficiencies

Let me tell you a story: I tried cutting costs by buying materials in bulk. This idea seemed great until the storage filled up completely! Bulk buying reduces cost per unit but needs careful storage planning. Long-term supplier deals can keep prices steady, but managing them requires much effort.

- Bulk Purchases: Lower unit costs but demand extra storage.

- Long-Term Contracts: Offer price stability but need strong supplier management.

Balancing these savings with timely delivery feels like a delicate task.

Reliability of the Supply Chain

A reliable supply chain works like a perfect machine. If one part fails, the process stops. I have spent nights worrying about shortages or issues in logistics. Strong relationships with suppliers have helped me, as has having a good backup plan.

- Supplier Relationships: Trust and communication lead to reliable service.

- Contingency Planning: Being ready for disruptions lowers risks.

Understanding these aspects of sourcing materials taught me the importance of being proactive. Watching lead times, saving costs smartly, and ensuring supply chain reliability helps keep operations in sync with market demands supply chain8. Avoiding delays is crucial; maintaining a competitive edge is important too.

Supplier location affects lead times.True

Proximity to production sites reduces shipping time, impacting lead times.

Bulk purchases always speed up production timelines.False

While cost-effective, bulk purchases may require extra storage, affecting timelines.

What Compliance and Certification Costs Should You Prepare For?

Business owners often encounter the complex world of compliance and certification. Regulatory fees and hidden costs can add confusion. Understanding these expenses is crucial. This knowledge keeps businesses both compliant and competitive. Business success relies on this understanding.

Compliance and certification costs differ widely across industries. They usually contain regulatory fees, audit expenses, documentation and training costs. Planning for these expenses helps avoid surprise financial problems. It keeps business operations smooth.

Understanding Compliance Costs

I remember my first experience with compliance costs for my business. It felt like solving a puzzle with too many pieces. Each piece showed a different expense.

Regulatory Fees: These are unavoidable charges. They remind you who controls the rules and show you are meeting industry standards.

Audit Expenses: Regular audits can be stressful. Once, I hired an external auditor who provided insights worth the cost.

Documentation and Filing: Paperwork might feel endless, but it is crucial. I found this out the hard way when a small mistake caused a big problem.

Training Costs: Keeping the team updated is important. We invested in some excellent courses. I complained at first, but they proved very valuable.

The Role of Certification

Getting certified feels like a big step. It shows everyone you care about standards.

| Certification Type | Cost Range | Renewal Frequency |

|---|---|---|

| ISO Certification | $5,000 - $15,000 | Every 3 years |

| CMMC Compliance | $3,000 - $10,000 | Annual |

| SOC 2 Type 2 | $10,000 - $50,000 | Annual |

Note: Costs change with business size and complexity.

Hidden Costs of Compliance

Some costs surprised me:

Lost Productivity: Every hour on compliance took time from our main business activities.

Opportunity Costs: Spending on compliance sometimes felt like losing chances for growth or new ideas.

Planning for Compliance Expenses

To manage things well:

Budgeting for Compliance: Setting aside money for expected and surprise needs saved me many troubles.

Investing in Technology: Tools like compliance management software helped us a lot. Check out automation tools9 to simplify your tasks.

Seeking Expert Advice: Hiring consultants felt like having a guide through the compliance maze. Consider using consultant services10 for tailored advice.

Understanding these factors helps me stay calm about compliance and certification. I feel ready to face any financial challenges from regulations.

ISO certification costs $5,000 - $15,000 every 3 years.True

ISO certification fees are generally between $5,000 and $15,000 for renewal every three years.

SOC 2 Type 2 compliance is renewed every 3 years.False

SOC 2 Type 2 compliance requires annual renewal, not every three years.

Conclusion

Custom underwear production involves hidden costs like sampling, materials, labor, compliance, and minimum order quantities. Understanding these expenses is crucial for effective budgeting and successful product launches.

Discover tips on finding affordable specialty fabrics to lower production costs. ↩

Learn methods for calculating labor costs to better manage your project budget. ↩

Explore how rapid prototyping can reduce time and costs in fashion design. ↩

Learn about typical MOQ expectations across different industries, helping you plan purchases effectively. ↩

Discover how MOQs affect new product launches in the fashion industry. ↩

Explore flexible pricing options that can help manage MOQ-related costs. ↩

Find suppliers offering lower MOQs, ideal for startups testing new markets. ↩

Explore factors that influence lead times to better manage production schedules and avoid delays. ↩

Discover tools that streamline compliance processes and reduce costs. ↩

Explore expert consultancy services for effective compliance management. ↩