Exploring the world of seamless underwear production feels like a maze filled with complex challenges and exciting opportunities.

Key technical challenges in producing seamless underwear involve choosing the right materials. Applying hot melt adhesive correctly is important. Achieving a good fit and comfort for different body types matters a lot. Brands need to focus on these to succeed. Ensuring durability while reducing waste is another challenge. Understanding these issues helps companies really succeed in this market. This understanding is very important.

When I first entered the world of seamless underwear production, I discovered its complexity. It is not just about creating comfortable clothes. Precision and innovation play a critical role. Selecting the right materials is essential. The fabric should hug the body correctly. Applying hot melt adhesives needs flawless execution. Each step demands careful attention and expertise.

I remember struggling with fabric choices. Finding the perfect blend of stretch and durability was challenging. The garments must withstand everyday wear. Fit also plays a crucial role. Every body differs and achieving comfort for all shapes can be difficult. It really is a daunting task. Overcoming these hurdles brings great satisfaction. It truly is what makes this industry rewarding.

Material selection is a key challenge in seamless underwear manufacturing.True

Choosing the right materials affects comfort, durability, and production efficiency.

Seamless underwear manufacturing does not require hot melt adhesives.False

Hot melt adhesives are essential for bonding materials in seamless underwear production.

How Does Material Selection Shape the Comfort of Seamless Underwear?

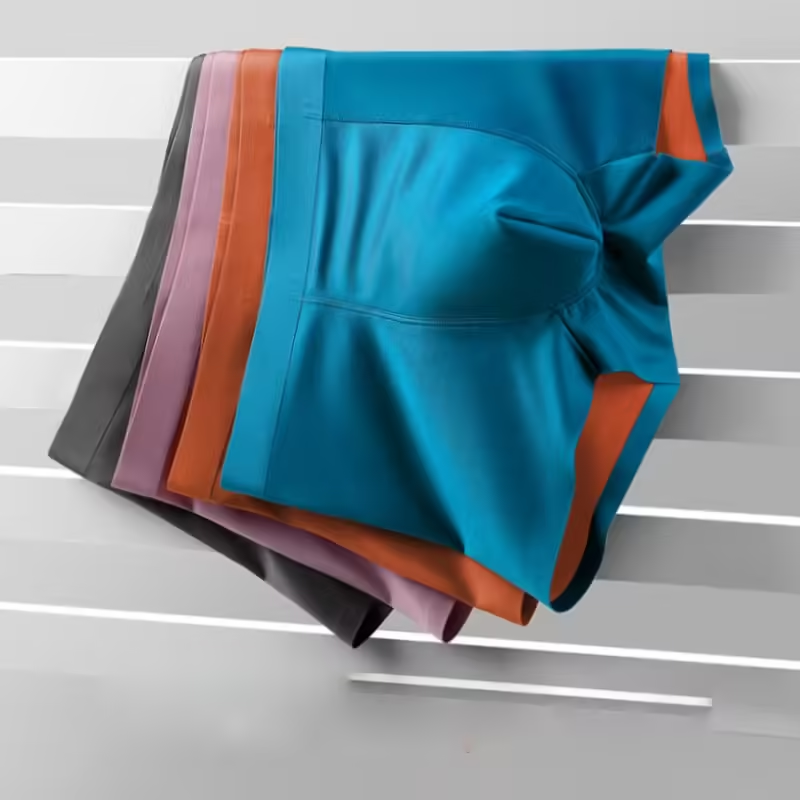

Material selection shapes seamless underwear. This choice is key to comfort and style. The right fabric makes a real difference. Ordinary items become extraordinary with the correct material.

Choosing materials is crucial in seamless underwear production. Materials influence comfort, durability, fit and quality. Correct fabrics probably result in superior performance. This often leads to happy customers.

Importance of Material Selection in Seamless Underwear Production

Material selection is crucial in seamless underwear production. It affects comfort, durability, and fit. The right fabrics provide a good feel against the skin.

I remember my first pair of nylon and spandex underwear. It felt like wearing nothing at all - light and breathable with just enough stretch to move. Everyone should have that experience with every pair.

Common materials include nylon, spandex, and cotton blends. Nylon offers durability and moisture control. Spandex provides stretch for a good fit. Cotton is comfortable but needs careful blending to stay elastic.

Key Factors to Consider in Material Selection

Comfort: Softness and breathability are essential. Fabrics that move moisture away keep you comfortable all day. Explore comfort fabrics1.

Durability: High-stress areas like waistbands require strong materials. These materials withstand wear, keeping customers returning for more.

Stretch and Recovery: A fabric's ability to stretch and return to its original shape is important. A good blend of spandex performs well.

Sustainability: Eco-friendly materials attract me as I learn about fashion. Organic cotton or recycled fibers appeal to me and many others looking for sustainable options. Learn more about sustainable fabrics2.

Production Efficiency: Chosen materials should allow fast manufacturing without losing quality. Efficiently processed fabrics reduce production time.

Material Comparison Table

| Material | Comfort Level | Durability | Stretchability | Sustainability | Cost |

|---|---|---|---|---|---|

| Nylon | High | High | Moderate | Low | Medium |

| Spandex | High | Moderate | Very High | Medium | High |

| Cotton Blend | Very High | Moderate | Moderate | High | Medium |

| Organic Cotton | High | Moderate | Low | Very High | High |

Technology's Role in Material Application

Hot melt adhesive technology helps create seamless designs. It bonds fabric layers without traditional seams while keeping comfort intact. Precise glue application is key to maintaining the fabric's feel.

Fit and Customization Challenges

Seamless underwear fit varies with body type, needing materials that suit different shapes and sizes effectively. Proper elasticity ensures a comfortable fit without losing shape.

Understanding material selection complexities helps brands produce high-quality seamless underwear that meets customer expectations for comfort, durability, and style.

Nylon is a durable material for seamless underwear production.True

Nylon offers high durability and moisture-wicking properties, making it ideal for seamless underwear that withstands wear while maintaining comfort.

Organic cotton is the least sustainable fabric option available.False

Organic cotton is considered very sustainable due to its eco-friendly farming practices, contrary to this claim's assertion.

How Does Hot Melt Adhesive Technology Affect Design Integrity?

Hot melt adhesive technology has truly changed the game in product design and manufacturing. But how does this innovative glue really impact design integrity? Let's dive deeper into its transformative effects!

Hot melt adhesive technology improves design integrity. This allows for smooth constructions that keep both looks and function intact. Strong bonds provide durability and they probably use materials efficiently to reduce waste. The precise application method protects quality control during production.

Understanding Hot Melt Adhesive Technology

Hot melt adhesive (HMA) technology plays a crucial role in modern design and manufacturing processes. This thermoplastic adhesive is applied in a molten state and solidifies upon cooling, forming a strong bond between materials. The precision of application is vital to ensure that the integrity of the design is maintained.

Key Benefits:

- Versatility: HMAs can bond a wide range of materials, including plastics, metals, and fabrics, making them suitable for various applications.

- Rapid Bonding: As they set quickly, they enhance production efficiency without compromising quality.

For more on the properties of hot melt adhesives3, click here.

Impact on Design Integrity

The use of hot melt adhesives significantly impacts design integrity through several key factors:

Seamless Designs:

Seamless constructions rely heavily on HMAs for maintaining structural integrity without traditional stitching. The precision in application ensures that no excess adhesive affects the aesthetics or functionality of the product.Durability:

Hot melt adhesives provide robust bonding strength, ensuring that products can withstand wear and tear. This is particularly important in high-pressure areas such as waistbands in underwear.Material Control:

Proper application techniques minimize waste and ensure that the right amount of adhesive is used. This not only reduces costs but also ensures that the final product meets quality standards.

| Factor | Impact on Design Integrity | Example Use |

|---|---|---|

| Seamless Designs | Eliminates visible seams, enhancing aesthetic appeal | Activewear, lingerie |

| Durability | Ensures longevity of products under stress | Outdoor gear, footwear |

| Material Control | Reduces waste and optimizes cost-effectiveness | Mass production of apparel |

For insights on sustainable practices in adhesive technology4, click here.

Precision Application and Quality Control

Maintaining the integrity of designs with HMA technology hinges on precise application techniques. Here are some critical aspects:

- Temperature Control:

The adhesive's viscosity is highly dependent on temperature; too hot or too cold can lead to poor bonding. - Equipment Calibration:

Regular maintenance of adhesive application equipment ensures consistent results and high-quality output.

To explore more about best practices for HMA application5, click here.

Challenges and Considerations

Despite its advantages, there are challenges associated with hot melt adhesives:

- Cost of Equipment:

Specialized application machinery can be expensive, impacting the initial investment for manufacturers. - Training Requirements:

Staff must be trained to handle both the materials and equipment effectively to avoid errors that could compromise design integrity.

For further details on training programs for adhesive technology6, click here.

Hot melt adhesives ensure seamless designs in products.True

HMAs eliminate visible seams, enhancing the aesthetic appeal and structural integrity of products like activewear and lingerie.

Training is unnecessary for using hot melt adhesive technology.False

Proper training is essential for staff to handle materials and equipment, ensuring design integrity is not compromised during production.

What Strategies Can Ensure a Perfect Fit for Diverse Body Shapes?

Finding clothes for different body shapes often feels overwhelming. But there's no need for that. Here are some helpful strategies. These tips improve comfort. They also help you show off your unique style.

Understanding your body type helps achieve a perfect fit for diverse shapes. Select suitable fabrics for better comfort. Offer customization options to meet specific needs. Use technology for new and innovative fits. Maintain strict quality control to deliver consistently good products. Embrace sustainable practices for an eco-friendly approach.

Understanding Body Shapes

Recognizing different body shapes is one of the first steps to achieving the perfect fit. When I understood my own shape, it was like a light turning on! There are some common body shapes people might relate to:

| Body Shape | Characteristics |

|---|---|

| Apple | Wider shoulders and bust, narrower hips |

| Pear | Wider hips, smaller bust, and defined waist |

| Hourglass | Balanced bust and hips with a defined waist |

| Rectangle | Similar bust and hip measurements with little waist definition |

| Inverted Triangle | Broader shoulders and bust, narrower hips |

Knowing your body shape can help you choose styles that look great on you.

Fabric Selection for Comfort and Fit

The choice of fabric is very critical for a good fit. I have worn clothes that looked nice but felt very tight because of bad fabric choice. Right materials should offer:

- Elasticity: Move easily without restrictions.

- Durability: Last well in areas like waistbands.

- Breathability: Stay comfortable all day.

Choosing cotton blends or spandex really changed my wardrobe. I now feel both comfortable and stylish.

Customization for Individual Fit

Customization is a wonderful solution for finding the perfect fit. I remember going to a store offering made-to-measure clothes and it felt luxurious! Customization adapts to different body shapes with:

- Made-to-Measure: Tailored clothes based on your size feel like a second skin.

- Adjustable Features: Elastic waistbands or straps help a lot.

- Diverse Sizing Options: More sizes mean everyone finds something that fits well. Discover more about custom sizing solutions7.

Fit Technology and Innovations

Technology has really changed the way we approach fitting clothes. I recently tried a virtual fitting room and it was impressive! Some technologies changing our thoughts on fit include:

- 3D Body Scanning: Captures precise measurements for customized patterns.

- Virtual Fitting Rooms: Try clothes virtually, saving time and reducing returns.

- Data Analysis: Predicts styles that suit various body shapes using customer data. Explore fitting technology advancements8.

Importance of Quality Control

Quality is very important for good fit. I have faced disappointment with poorly fitting clothes that didn’t last. High-quality production standards involve:

- Regular Inspections: Consistency in all products is crucial.

- Feedback Loops: Listening to customers helps improve continuously.

- Prototype Testing: Testing samples before mass-producing them can save many problems. Read more on quality control practices9.

Sustainability in Sizing Solutions

Sustainability is very important to me and is becoming vital in fashion. Consider these factors:

- Eco-friendly Materials: Sustainable fabrics that give comfort are essential.

- Waste Reduction: Patterns that reduce fabric waste while fitting well are significant.

- Ethical Production Practices: Working with manufacturers who support ethical labor is critical. Find out more about sustainable fashion strategies10.

Understanding body shapes aids in selecting the right clothing.True

Identifying body shapes helps customers choose styles that fit well and enhance their appearance.

Sustainable fabrics do not provide comfort in clothing fit.False

Eco-friendly materials can still offer flexibility and comfort, essential for diverse body shapes.

How Can Manufacturers Balance Durability with Environmental Sustainability?

I have traveled through the complicated world of manufacturing. I understand the challenge of combining strong products with an eco-friendly approach. This task involves very creative ideas. It also needs true devotion to preserving our environment.

Manufacturers probably balance durability with environmental sustainability by choosing eco-friendly materials. They also optimize production processes. They use strategies to reduce waste. They have strict quality control. They work with sustainable suppliers. This comprehensive approach meets consumer demands. It also protects our planet. Our planet really needs protection.

Material Selection and Sourcing

Choosing sustainable materials is critical for manufacturers aiming to balance durability with environmental sustainability.

For instance, using organic cotton or recycled polyester can significantly reduce the environmental footprint compared to conventional materials. Manufacturers must also consider the lifecycle of these materials, ensuring that they are not only durable but also responsibly sourced and biodegradable when possible.

Example: Many brands are now adopting materials like Tencel, made from sustainably sourced wood pulp, which offers both durability and a lower environmental impact.

Production Processes

Another area where manufacturers can focus is on optimizing production processes.

Incorporating efficient production techniques, such as lean manufacturing, can help minimize waste and energy consumption. Using hot melt adhesive technology allows for seamless designs that reduce fabric waste and enhance durability, as this method typically requires less material than traditional sewing.

| Process Improvement | Benefits |

|---|---|

| Lean Manufacturing | Reduces waste, increases efficiency |

| Hot Melt Adhesive | Enhances durability, minimizes seams |

Waste Reduction Strategies

Manufacturers can implement various waste reduction strategies to ensure environmental sustainability.

By precisely controlling material usage, companies can minimize fabric waste. Additionally, adopting a circular economy approach allows for recycling materials from old products into new ones, thus promoting sustainability without sacrificing durability.

Case Study: Brands like Patagonia have set examples in their industry by encouraging customers to return worn items for recycling, demonstrating how sustainability can be integrated into product life cycles.

Quality Control and Durability Testing

To ensure that products maintain durability while being environmentally friendly, manufacturers must implement rigorous quality control measures.

Regular durability testing is crucial to ensure that the final product meets consumer expectations. This involves evaluating the performance of various materials under different conditions and making adjustments to improve resilience without compromising on eco-friendliness.

Tools for Testing Durability:

- Tensile strength testers

- Abrasion resistance testers

- Water resistance testers

Collaboration with Sustainable Suppliers

Partnering with suppliers who prioritize sustainability in their production practices can further enhance a manufacturer’s commitment to environmental responsibility.

This means sourcing from suppliers who use renewable energy sources, minimize waste in their operations, and provide transparency regarding their sourcing practices. Collaboration can lead to innovations that ensure high-quality, durable products that are also sustainable.

Benefits of Sustainable Partnerships:

- Enhanced brand reputation

- Access to sustainable materials and technologies

- Shared knowledge on best practices in sustainability

Using recycled polyester reduces environmental footprint.True

Recycled polyester significantly lowers the ecological impact compared to conventional materials, promoting sustainability in manufacturing processes.

Lean manufacturing increases waste during production.False

Lean manufacturing is designed to minimize waste and enhance efficiency, contradicting the claim that it increases waste during production.

Conclusion

This article explores the technical challenges in seamless underwear manufacturing, focusing on material selection, fit customization, hot melt adhesive technology, and sustainable practices.

Understanding material selection in seamless underwear will enhance your knowledge of fabric performance and influence your buying decisions. ↩

Explore sustainable options in seamless underwear manufacturing to align with eco-conscious consumer trends. ↩

This link will provide detailed insights into how hot melt adhesives influence design integrity across various industries. ↩

Learn more about sustainable practices in adhesive technology to enhance your understanding of eco-friendly options. ↩

Discover best practices for applying hot melt adhesives to ensure product quality and design integrity. ↩

Explore training programs available for staff to master the use of hot melt adhesives effectively. ↩

Explore this link to discover tailored clothing options that cater to all body types, ensuring everyone finds their perfect fit. ↩

Learn about innovative technologies that enhance fitting accuracy and customer satisfaction in fashion. ↩

Understand how quality control practices can impact the fit and satisfaction of your clothing line. ↩

Discover sustainable practices that not only benefit the environment but also enhance the quality and fit of garments. ↩